The non-profit organisation nano-Control, International Foundation calls for mandatory rules for the installation and operation of ubiquitous toner-based printing systems like ‘laser printers and copiers’ to sustainably improve indoor air quality. The ban on inhalable PFAS in indoor environment is necessary.

Toner and Emissions of Laser Printers

Manufacturers of toner for laser printers disclose their toner compositions in patents. The safety data sheets only contain information that is legally required. Components of the polymers do not have to be named, only hazardous substances in larger quantities, according REACH regulation.

The toner mixtures are recipes for a highly technical electrostatic process based on precision. All materials have their specific tasks and are added in certain proportions. These are not contaminants, but inventions by experts, to be found in the toner patents of the manufacturers.

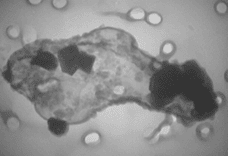

Element analysis contents toner particle („bubble“), (Fe) + ultrafine (Si)- + (Al)-containg particles. University Gießen, IPAS

The composition of the toner particles is basically formed from synthetic resin, pigments, magnetised metal oxides and various additives, like stabilisers, plasticisers, antioxidants, dispersing agents, substances that ensure electrical conductivity, thermal and chemical resistance. Other additives help to improve flowability and prevent moulding and rusting. The large group of metal complexes is used to generate an electrostatic charge.

Toner bubble Potentially toxic compounds may adhere to the surface of the toner particles, such as volatile organic compounds (VOCs), ethylbenzene, phenols, aldehydes or various carboxylic acids. 1

PFAS improving overall printing performance

Fluoropolymers materials are used in the production of printing inks and toners such as PTFE (polytetrafluoroethylene).2+3

PFAS are additives to toner formulations to enhance the performance and quality of the printing process in various applications:

Improving Flow Properties: They reduce friction and improve the flowability of toner particles, ensuring a more uniform distribution and smoother printing process.

Anti-Sticking Properties: They prevent toner from sticking to sensitive components, such as the fuser unit or rollers, thereby extending the lifespan of these parts and reducing maintenance. Particularly crucial in the fuser units of laser printers, where high temperatures are involved.

Enhancing Toner Transfer: Fluoropolymers optimize the electrostatic properties of toner, allowing for more precise transfer of the toner image onto paper. Used in color and monochrome laser printers as well as high-quality copiers.

Wear Protection: Adding fluoropolymers reduces abrasion of toner on mechanical components, improving the overall performance of the printer. Beneficial for printers designed for high-volume printing tasks.

Resistance to Heat and Chemicals: Fluoropolymers withstand extreme conditions, enhancing toner stability at high temperatures and under chemical stress. Essential in high-performance printing systems and industrial printing processes.

These additives significantly improve print quality, efficiency, and the longevity of printing systems.

In addition to PTFE (polytetrafluoroethylene), there are other fluoropolymers more effective for certain applications in toners, e.g. PFA (perfluoroalkoxyalkanes), ETFE (ethylene tetra-fluoroethylene), TFE/PFPE copolymers (tetrafluoroethylene/ perfluoropolyether copolymers), PVDF (polyvinylidene fluoride). 4

The printing process of a laser printer produces billions of ultra-fine particles consisting of micro- and nanoplastics mixed with heavy metals, chemicals, VOCs and PAHs with just one page of print. The composition is largely unknown.

toner dust on the hands + printer emissions in the air Canva Dream Lab – KI generiert

Manufactured fluoropolymers may contain unintentional residues of perfluorinated alkyl acids, which do not dissolve out of the material under normal conditions, but unsure under high heat at 200 °C printing and melting on the paper.

- PFAS are of concern in the overall view of the product life cycle and beyond. Non-polymeric PFAS are released in the course of all known manufacturing processes and contaminate the environment to varying degrees (Glüge et al., 2020).

- PFAS do not degrade under environmental conditions or only over a very long period of time and are known as perpetual chemicals. Some of these chemicals are also suspected of being carcinogenic.

- PFAS can enter the body via the food chain, drinking water and the air we breathe. They accumulate in the blood and organ tissues. These chemicals are only excreted very slowly.

Effects on Health

PFAS

The effect on the immune system is perhaps the most important health effect of PFAS, because a dysregulated immune system is the basis for many diseases. So far, manufacturers have only had to show whether a substance is carcinogenic, teratogenic or neurotoxic. Manufacturers do not have to test the effect of a chemical on the immune system and for this reason it is not investigated.

All PFAS, whether short-chain or long-chain, either cannot be degraded or turn into other equally non-degradable PFAS in the environment. And they can be found everywhere. According to a study from 2020, everyone in Germany is contaminated with PFAS.5

Toner and Emission of Laser printers

UFP cross the blood-lung&brain-barrier, reach the amygdala and the central brain via the olfactory bulb. Inflammatory and immunological response occurs, respiratory, cardiovascular, and other disorders effects appear shortly after exposure. 6

This can cause symptoms such as sneezing, runny nose, sore throat, dry cough, asthma or COPD, inflammation of the eyes, bladder or skin, stomach pain, headache or muscle pain and extremly tiredness (exhaustion).

For many years we have been receiving reports from people affected, some of them seriously ill, who have often been exposed to emissions from toner-based laser printers and copiers for years and decades. nano-Control has initiated investigations, analysed 70 toners for metals, and those affected have provided test results.

They all bear the consequences of long-term exposure. Toner polymers consist of hundreds of different micro- and nanoplastic particles, mixed with metals and chemicals, the composition of which is largely unknown. Individual substances, such as PFAS, cause illnesses that are reported daily by those affected, including cancer.

2,000 reports have now been analysed by the University of Massachusetts Lowell.

Self-reported symptoms associated with the use of printer and photocopier machines: Results from the nano-Control, International Foundation survey“

Visible toner dust” – a surrogate for exposure to printer-emitted particles (PEP) – was a strong predictor of several health outcomes, including chronic fatigue, bronchial hyperreactivity, asthma/COPD and cardiovascular disease, as shown by the high and statistically significant adjusted odds ratios. 7

Call for Mandatory Indoor Air Rules

For the first time, the WHO has issued an air quality guideline on ultrafine particles (UFP): ‘High particle number concentrations (PNC) can be considered >10,000 particles/ cm3 (24-hour average)’ This directive also applies to laser printers that emit UFP indoors. 8

Mandatory rules can be used to restrict PFAS. However, the goal remains that a ban on PFAS is necessary. Inhalable perpetual chemicals in indoor air are unacceptable.

In 2007, polymers and their components were exempted from regulation under REACH as mixtures. This has not changed to this day.

These largely unknown components are increasingly becoming a problem for humans and nature. It is the incredible quantity of individual substances, but also the total quantity, that is released into the environment every year.

Circular economy and supply chain law Products cannot be regulated if the compositions are completely unknown.

At some point, even the smallest contaminant become a major problem.

The German Federal Ministry for the Environment has no information on the quantities and periods of PFAS use, not even on whether the respective area of use is relevant for Germany at all. 9

“PTFE/wax blends are used for their strong rub resistance and slip effect, but rising concerns about their regulatory and sustainability profile increases the need for PTFE free alternatives.“

Mandatory rules for ultrafine emissions from e.g. laser printers and 3-D-printers are necessery. The ban on inhalable PFAS is necessary.

Author:

Heike Krüger, Chairwoman

nano-Control International Foundation

Sources

- https://en.air-q.com/blog/air-q-lab-gefahr-ultrafeinstaub-aus-dem-drucker-wir-haben-nachgemessen

- Glüge et al. 2020. An overview of the uses of per- and polyfluoroalkyl substances (PFAS)

Environ Sci Process Impacts. 2020 Dec 1;22(12):2345-2373. doi: 10.1039/d0em00291g. Epub 2020 Oct 30. - Ink and Toner Additives Add to the appeal of printed products

clariant.com/en/Business-Units/Additives-and-Adsorbents/Waxes/Inks-and-Toners - Toner compositions with surface additives Patent US7288352B2

- PFAS: Gefahr erkannt – und jetzt?

www.helmholtz.de/newsroom/artikel/pfas-gefahr-erkannt-und-jetzt/ - Nanoparticle exposures from nano-enabled toner-based printing equipment and human health: state of science and future research needs

Critical Reviews in Toxicology May 201747(8):1-27

DOI:10.1080/10408444.2017.1318354 - Self-reported symptoms associated with the use of printer and photocopier machines: Results from the nano-Control, International Foundation survey, J Occup Environ 2024 Aug 1, doi: 10.1097/JOM.0000000000003197

- Globale Luftgüteleitlinien der WHO: Feinstaubpartikel (PM2,5 und PM10), Ozon, Stickstoffdioxid, Schwefeldioxid und Kohlenmonoxid. Zusammenfassung ISBN: 978-92-890-5606-9 © Weltgesundheitsorganisation 2021

- bmuv.de/fileadmin/Daten_BMU/Download_PDF/Bodenschutz/pfas_leitfaden_bf.pdf

nano-Control

nano-Control

Hinterlasse einen Kommentar

An der Diskussion beteiligen?Hinterlasse uns deinen Kommentar!